Department of Mechanical Engineering publishes a research paper on Nano Energy about Triboelectric nanogenerators for electro-assisted cell printing

On November 9th, 2019, Associate Prof. Jia Cheng from the Department of Mechanical Engineering, Tsinghua University, in collaboration with Associate Prof. Rui Yao and Dr. Yijia Lu, published a research paper titled "Triboelectric nanogenerator for electro-assisted cell printing" online in Nano Energy.

Triboelectric nanogenerator (TENG) is a device based on triboelectrification and electrostatic induction that could convert various types of mechanical energy into electrical power. It has the strengths of simple structure, low cost, and high flexibility. The high voltage and low current characteristics of TENG have a unique advantage in high voltage conditions for capacitive load power supply. Modular tissue engineering is a bottom-up strategy of constructing and designing biological tissue, which can be used in cell transplantation, artificial organs, etc. The cell-laden hydrogel microspheres are most commonly investigated since they demonstrate more uniform interconnections and better mechanical properties than cylinder, and a three-dimensional (3-D) microenvironment. The electro-assisted cell printing technology produces relatively monodispersed, bioactive, shape and size controllable microspheres. However, previous research often relied on commercially available equipment such as direct-current or pulsed HV power sources (5-20 kV), making the system more complicated and expensive. As a new type of high voltage power source, TENG can make cell printing technology more simple and efficient.

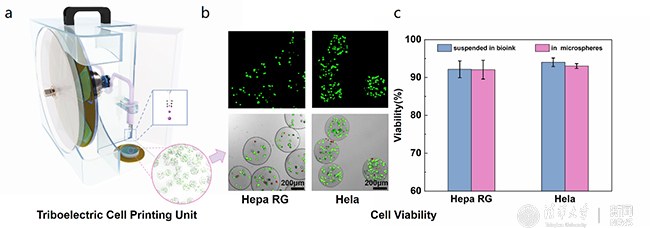

Fig. 1 Triboelectric assisted cell printing :(a) Conceptional schematic of triboelectric cell printing (b) HepaRG and Hela cells after reactive fluorescence staining (c) Comparison of the survival rate of HepaRG and Hela cells

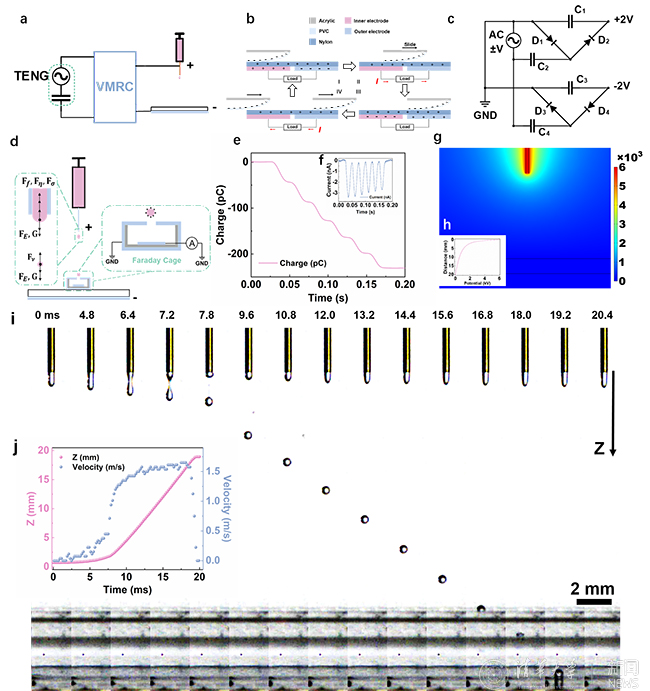

Jia Cheng’s and Rui Yao’s groups worked together to develop a triboelectric cell printing system, which consists of a freestanding-rotating-disk TENG (FRD-TENG), a voltage multiplier rectifying circuit (VMRC) and basic setup for cell printing. The FRD-TENG along with the VMRC delivered a direct-current high-voltage of 5-8 kV and then generated microsphere with uniform and spherical shape with an average diameter of 300 μm. HepaRG and Hela cells were mixed in materials for culture and achieved viability rates of more than 92% after printing. At the same time, the charge (34.40±4.48 pC) of the microspheres generated by TENG was lower and more stable than that of a commercially available power supplier (42.40±19.66 pC), demonstrating the advantage of electrosensitive cell printing. In addition, electrical analysis and multiple physical field simulation in COMSOL were conducted to uncover the mechanisms of the triboelectric cell printing method. Factor experiments were then conducted to determine the appropriate set-up for later research on 3-D cell culture. This method enriched the diversity of the cell printing process and can be conveniently utilized in bioprinting and biomanufacturing directly by mechanical energy stimuli in the future. It has a technical competitive advantage in the event that a traditional power supply is not available.

Fig. 2 Experiments of the triboelectric cell printing. (a). The electrical circuit of triboelectric cell printing. (b). The working principle of FRD-TENG. (c). The electrical circuit of the voltage multiplier rectifying circuit (VMRC). (d). The schematic of charge measurement of each microdroplet (e-f). The charge and current waveforms of the triboelectric cell printing process, respectively. (g-h). The simulation results of the potential distributions on the 2-D range and the Z-axis, respectively. (i). The dropping process of the microdroplet recorded by the high-speed camera (j). The displacement and velocity of one microdroplet recorded by the high-speed camera.

Jia Cheng, Rui Yao and Yijia Lu from the Department of Mechanical Engineering, Tsinghua University, are the corresponding authors. Hengning Huo and Fan Liu, graduate students (alumni) of the Department of Mechanical Engineering, Tsinghua University, are the co-first authors of this paper. Other authors include Yixue Luo, Qian Gu, Yuan Liu, Zhaozheng Wang, Ruoyu Chen, and Prof. Linhong Ji. This work is supported by the National Key Science and Technology Project, the National Key Research and Development Plan, the National Natural Science Foundation of China and the independent research project of Tsinghua university.

Article link: https://doi.org/10.1016/j.nanoen.2019.104150